Designing with Purpose

David Cervantes is bringing together local volunteers to make personal protection equipment for health care providers.

Like any maker, designer, tinkerer or DIY-er, David Cervantes is used to being in near-constant action. The compulsion to create informs his company, Cervantes Design. It is his outlet when he is feeling stressed. It is the tie that binds him to his peers within the St. Louis maker community.

Creating in the time of COVID-19 looks vastly different, however. With citizens being called to stay home as a form of civic duty, the human urge to do something in the face of crisis feels stifled. Cervantes certainly felt that conflict.

“The maker in me – all makers and tinkerers have it – feels that if I have the capacity and capability to do something, I am driven to do it,” Cervantes says. “Being idle goes against makers. A lot of us out there are going bonkers in our wood shops. Artists are out there in their garages painting up a storm. If we can help, we want to.”

Cervantes and his fellow makers would not stay idle for long. A few weeks ago, while scrolling through DIY threads on Reddit, the designer was struck with a call to action. Well aware of the shortage of personal protective gear for healthcare workers and first responders, he realized that he and his colleagues were better positioned than most to step in and fill the void. Inspired by the work of the German designer Josef Prusa, Cervantes went to his 3-D printer and made a plastic face shield that could serve as a first line of defense for healthcare workers. It was barely off the presses when he put out a call to his fellow St. Louis makers to see if anyone wanted to help.

The response was overwhelming.

“I just printed it out on a whim and put some feelers out,” Cervantes explains. “Within 48 hours, the momentum swelled up insanely. We’re all rallying around this cause.”

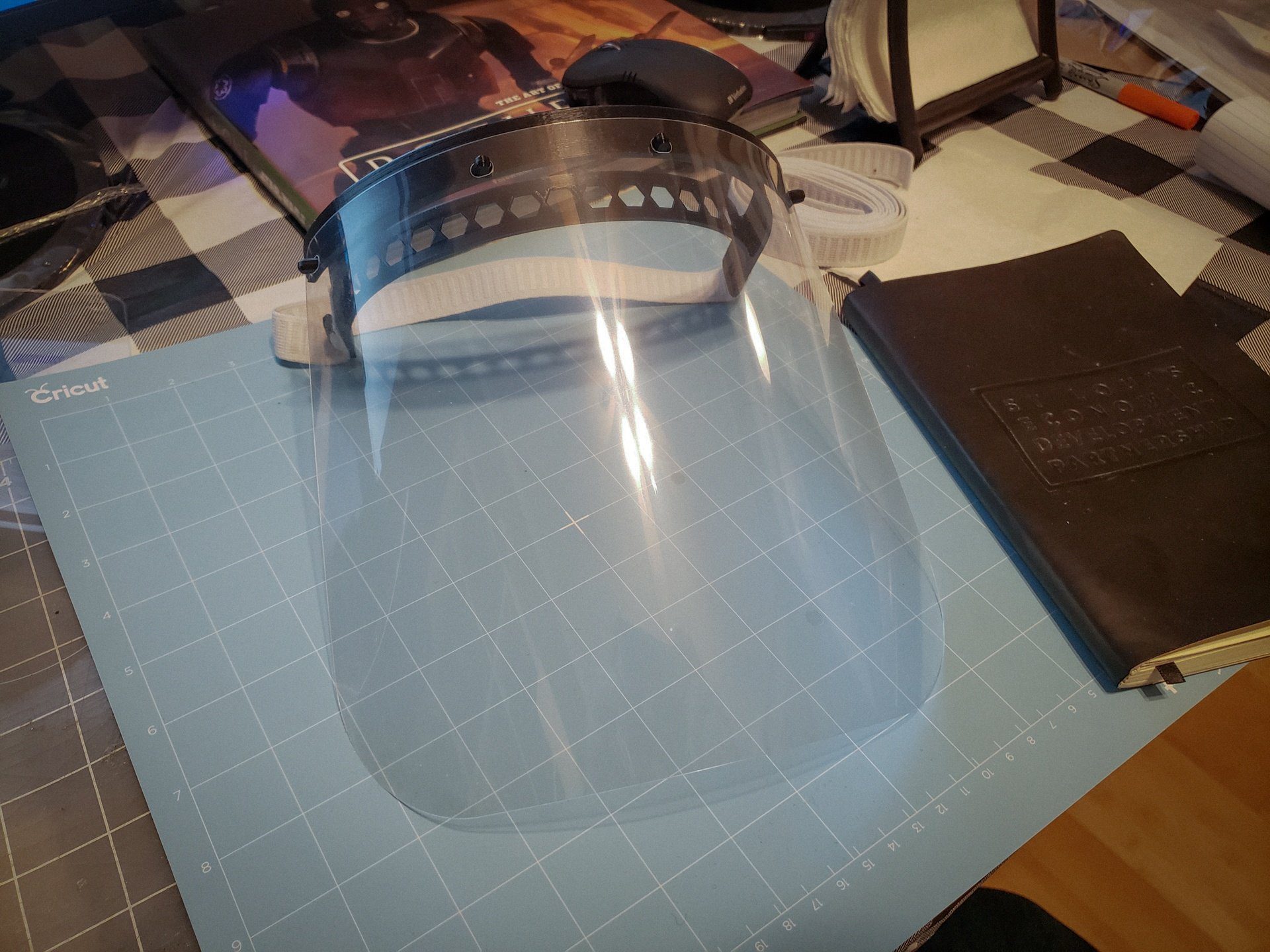

The face shield Cervantes and his fellow designers are producing is not meant to replace the N95 respirators that are so critical in protecting health care workers and first responders against COVID-19. Instead, they serve as a barrier that protects the mask in order to prevent them from becoming contaminated. Made from polyethylene terephthalate glycol (PETG), the shields can be wiped down with bleach or isopropyl alcohol to sanitize and reuse them. This helps extend the lifespan of the N95 masks, which are in short supply.

As Cervantes explains, N95 respirators are difficult to fabricate, but the shields he and his fellow makers can create are fairly easy to produce. All they require is a 3-D printer, a laser-cutter or cricut machine, sheets of PETG and elastic bands to hold the shields in place. For now, he and the other designers participating in the project have been relying on what they have on hand, but he admits they may have to turn to other materials to meet demand.

So far, that demand has been robust. Though he knew there was a need for such a product when he spearheaded the project, Cervantes was not sure if the traditionally bureaucratic healthcare community would be receptive to his efforts. However, when he reached out to local hospitals, he was greeted with enthusiasm and a request for 200 shields.

Cervantes and his collaborators made their initial drop-off to a local hospital on March 22, and, after receiving feedback from its health care providers, plan to ramp up production and expand the project to other organizations throughout the St. Louis area. Currently, he has thirteen other makers helping him create the shields, which will allow them to produce the 200 shields in one or two days. He is also working with Inventorforge in St. Charles County on making a version of the shields that does not need to be 3-D printed. If that works, they could reduce the time it takes to make one from five hours to two minutes.

Heartened by the overwhelming readiness to help he’s seen throughout the St. Louis region’s maker community, Cervantes can’t help but feel hopeful and immensely proud to be a part of such a group of doers.

“We all want to make this town better,” Cervantes says. “This bolsters my feelings about everything. If we can hunker down and all build together, we can do this. We landed on the moon; we can definitely figure this out.”